Water Production Monitoring System

Overview

Project objectives & Goals Objectives of implementing this system are to:

- Automatically send all sensing data over network using WIFI connection

- Ability to access the data from a local network or remotely over the internet as well (optional)

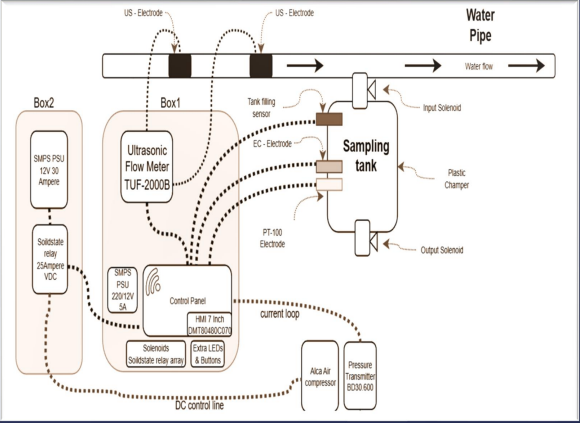

- Measuring water flow using non-intrusive ultrasonic probes or magnetic flow meter

- Measuring water conductivity and temperature through automatic sampling sub-system using small, connected tank and 2 solenoid valves to automatically fill a water sample then measure uS/CM and temperature parameter

- Measuring water level using pressure transmitter & Air compressor

- HMI Display local sensing data in the system box

- A solid-state relay will be added to board to switch on/off an air compressor based on pressure scenarios provided by the customer

How it works?

Flexible hose ¼‘’ is installed inside the well with open end below dynamic water level, and on the other connected to pressure sensor on surface (unsubmerged).

All sensors to be mounted on well head and sampling tank as well to allow sensors to take measurements instantaneously and periodically based upon customer requests.

Electronic PCB with LED monitor are mounted on well head, connected to the Sensors to measure and send all

physical parameters (Flow rate – Water level – Water Conductivity – Water Temperature) to online monitoring platform.

The Electronic PCB is connected to the internet using local Wi-Fi router to send water level readings 24/7. Readings can be monitored and archived for better monitoring & analysis experience.

Solution Architecture

Software/Hardware

Working conditions, limitations and accuracy

- Ability to consolidate and send all collected data on server side over an ethernet connection.

- Additional WIFI module on board to be able to access the internet over WIFI as well (optional).

- A relay is added to board to switch on/off an air compressor based on water level increases inside the well.

- Additional 12V 5-10A power supply is added to power the board, sensor and pump.

- Securing sensing data is available based on customer requirement.

- Hosting can be provided by through local network, open-source platform or private customized platform based upon customer requirements.

- Data acquisition over internet shall provide reporting system (.xls) file format, an alarming system for a specific incidence over tweeter, adding up a friendly use interface over web-based devices or mobile application.

- Data to be displayed on a screen monitor in filed for instantaneous measurements.

- Electronic board housing: – IP65 rating (Dust & Waterproof).

- Field working conditions:

- Field temperature (0-60) °C

- Water Level (0-300) m

- Electrical submersible pump (ESP) depth (10-300) m

Working conditions, limitations and accuracy

- EC Water sensor & Transmitter (Option 1)

- Isolated modbusrtu485 EC transmitter

- EC-Electrode 0-44000us (customizable from 2000 to 44000 uS)

- Electrode working temperature 10 up to 50 degree.

- Error 2% of Full scale

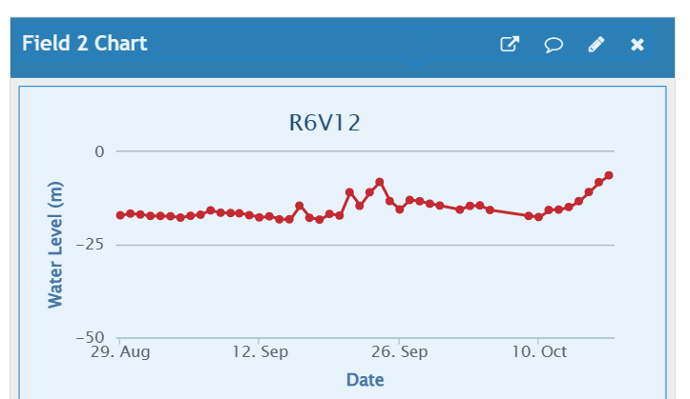

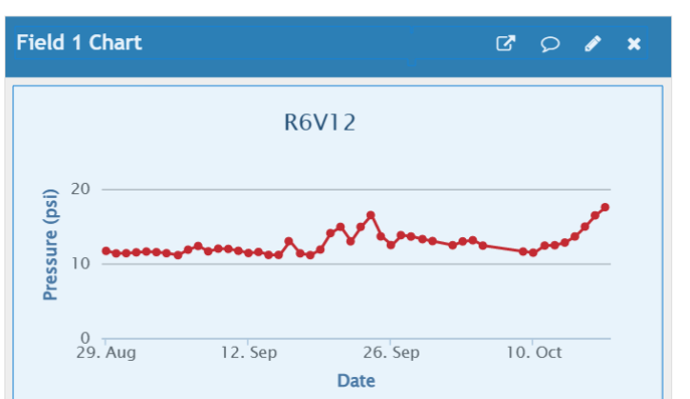

Monitoring Charts

Field Installation